Handling your success

In the majority of food production line installations, automated equipment is used to palletize bulk products.

These pallet loads are then stored temporarily in warehouses, during which the integrity of the primary package is controlled, before product is conveyed to a secondary packaging process.

These steps are required to check for any microbiological agents, which could evolve in the product.

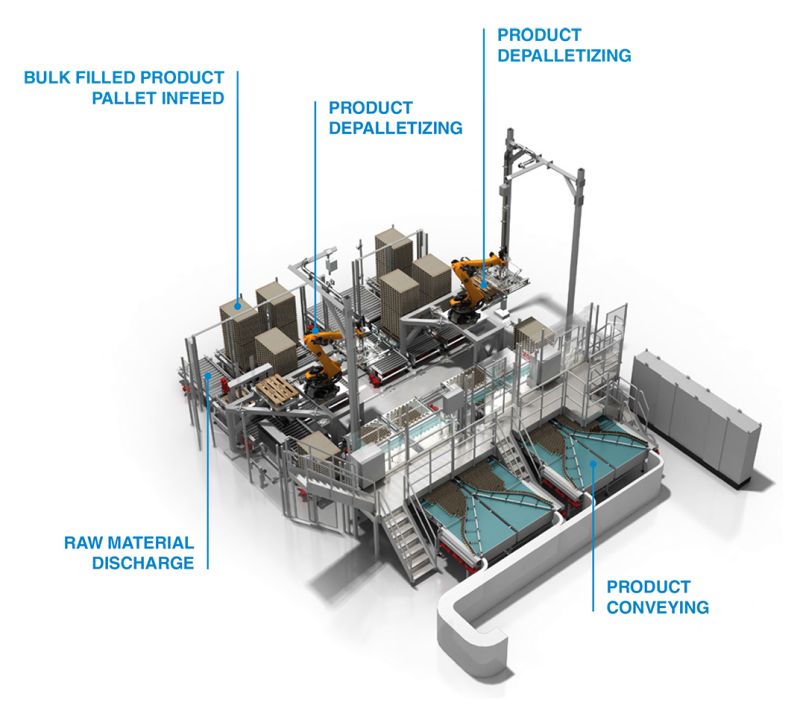

In FOOD & PET FOOD production, sometimes, after the autoclave treatment, products need to be stored temporarily in warehouses. Clevertech provides dynamic solutions that offer palletizing and depalletizing bulk products, which arrive from storage areas.

Clevertech’s solutions for the center of the packaging line, have two possible set ups: floor level installation or high level with operating platform; these can be customized according to the customer needs.

Clevertech systems can handle any type of container that comes from the front packaging line using three different type of product handling:

Long-term partnerships with world-leading FMCG companies allow Clevertech to understand that even minimum defects in bulk palletization or depalletization processes can lead to line stoppages.

As a result, Clevertech has developed automated solutions coupled to cameras systems.

These are linked to the robotic pick-and-place activities and can adapt them in real time according to the product presentation on the conveyor.