Handling your success

Clevertech is able to supply the lidmaking industry too, with different systems dedicated to conveying, accumulate, package and palettize lids.

Clevertech’s experience includes unwrapping lids to be seamed to cans, too. Indeed, looking to the company

roots, that is where everything started.

Our founder is an engineer who matured his experience in a can-lidmaking plant.

Due to over 30 years of success in the setting of lid systems, Clevertech has gained a lot of experience - facing different situations and finding innovative and efficient solutions. Thanks to established partnerships, Clevertech has collaborated in the realization of projects with the major machine makers in the sector, including Shell press, Conversion press, Oven and Vision systems.

In the engineering phase, thanks to its acquired knowledge, Clevertech is able to reduce the line’s design time and implement vertical start up.

One of the major complexities, in the project management for the realization of lids, is the transport phase.

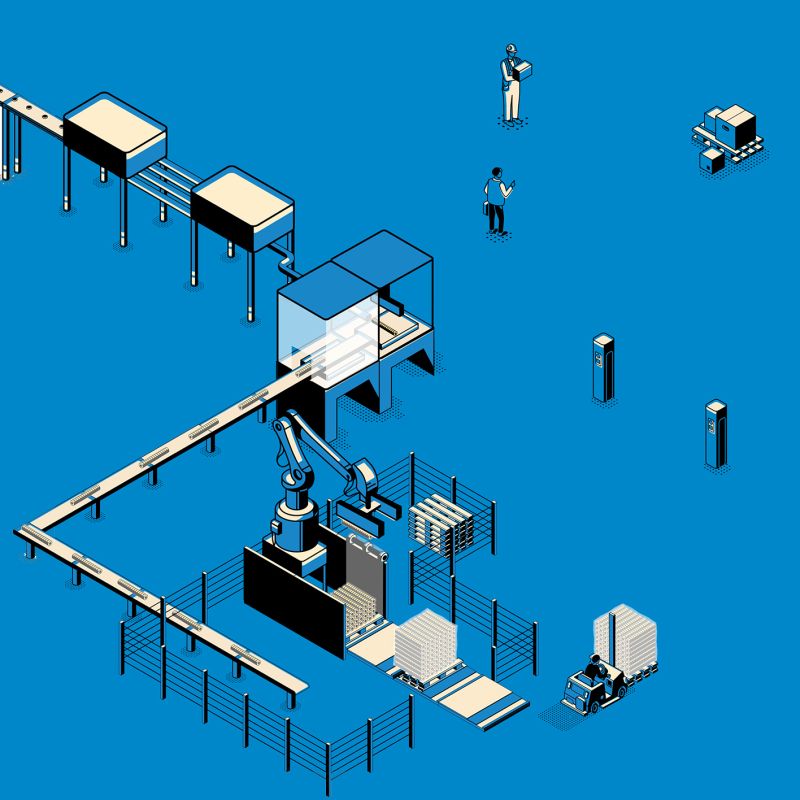

Clevertech designs and produces (in house) all the links and transport systems between the machines that make up the line.

Even the robotic systems that balance differences in the speeds, in the end production and also in the end line are built in Clevertech.

Everything is totally integrated.

A key element for obtaining line efficiency and reaching the maximum flexibility is the correct design of the transportation during the lidtransformation phase.

The technologies for the handling of lids can be:

For balancing the disparities in production speed, and also to give customers the ability to change shapes without any line stoppages, it’s possible to deploy robotic or traditional systems with magnetic or mechanical handling?

A Clevertech lid line comprises palettization, strapping, stretch wrapping and labelling. 9 different types of lids can be handled by Clevertech solutions: