Handling your success

In the FOOD or PET FOOD segment, Clevertech can provide product handling solutions in a wet environment, adopting the best guidelines in terms of TPM, guaranteeing reduced maintenance times with streamlined operations and Clean Design plant structures.

In the FOOD and PET FOOD world, Clevertech provides product-handling systems for wet environments, embracing the Clean Design system guidelines.

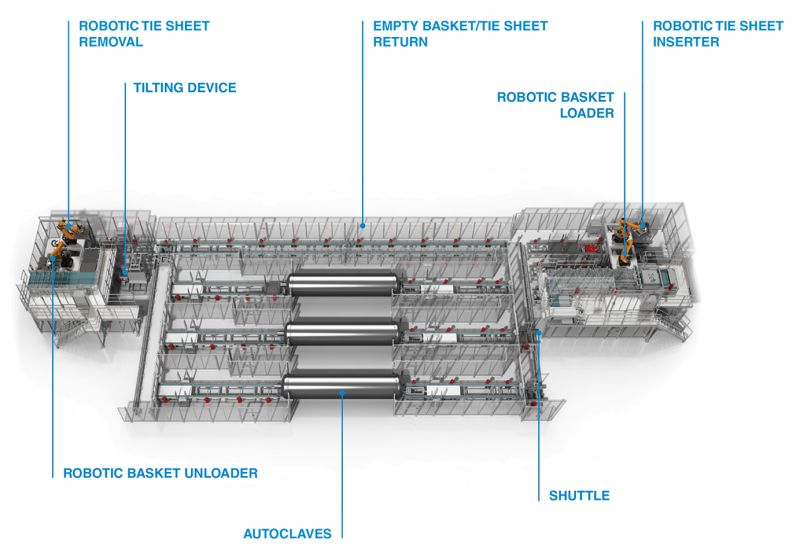

Clevertech’s loading and unloading basket solutions offer two possible setups: robotic or cartesian. In both configurations, the system recycles empty basket and layer pads without any operator intervention during the production phase.

The Clevertech systems can handle any raw materials coming from the front of packaging line, using three different types of product handling:

The Clevertech system can handle different types of containers such as:

The footprint of the system is determined by the required production yields and the different product treatment times required.

It is available a complete integration and management of derived data from loading - unloading in connection to autoclaves to monitor and handle the product treatment managing different products simultaneously.

Using the HMI, the operator can visualize the processing status of the autoclaves and - at the same time - can undertake quality control of the product. It is also possible to track all baskets location using the HMI.

During the basket unloading process, different dryer system can be combined to get product ready for secondary packaging formation.

Clevertech has developed multiple solutions in the basket-unloading process to manage different multi flavored configurations.